Introduction to the offset printing process

The offset printing process is one of the most widely used methods for reproducing printed materials. It is a highly efficient and cost-effective technique that is commonly used in the production of newspapers, magazines, brochures, and many other types of printed materials. This article will provide a comprehensive overview of the offset printing process, including its history, key components, and advantages.

The History of Offset Printing

The offset printing process has a rich history that dates back to the late 19th century. It was first developed by a man named Robert Barclay in the United States, who invented the offset lithography process. This revolutionary printing technique quickly gained popularity due to its ability to produce high-quality prints at a relatively low cost.

The Key Components of Offset Printing

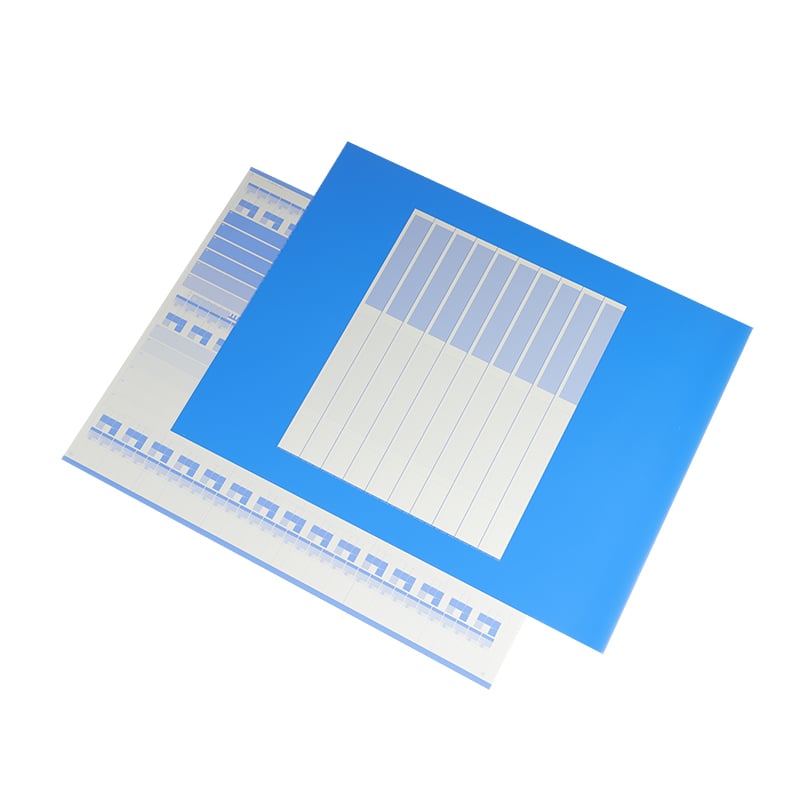

There are several key components involved in the offset printing process. These include the printing plate, the offset cylinder, the ink fountain, and the blanket cylinder. The printing plate is typically made of aluminum and contains the image that needs to be printed. The offset cylinder transfers the image from the plate to the blanket cylinder, which then transfers the image onto the paper. The ink fountain holds the ink, which is transferred to the printing plate.

The Advantages of Offset Printing

Offset printing offers a number of advantages over other printing methods. One of the main advantages is its ability to produce high-quality prints with excellent image reproduction. The offset printing process also allows for a wide range of paper types and finishes to be used, giving designers and printers greater flexibility in their projects. Additionally, offset printing is highly efficient and can produce large volumes of prints in a relatively short amount of time.

The Offset Printing Process Step-by-Step

The offset printing process can be divided into several distinct steps. First, the image is transferred from the computer to the printing plate using a process called prepress. Next, the printing plate is mounted onto the offset cylinder and ink is applied to the plate using the ink fountain. The inked image is then transferred from the plate to the blanket cylinder, which in turn transfers the image onto the paper. Finally, the printed sheets are cut and finished to the desired specifications.

The Role of Technology in Offset Printing

Over the years, advancements in technology have greatly improved the offset printing process. Computer-to-plate (CTP) technology, for example, has replaced the traditional method of using film to create printing plates. This has resulted in faster plate-making times and improved image quality. Additionally, digital printing technology has allowed for greater customization and personalization in offset printing, making it an even more versatile and adaptable printing method.

The Environmental Impact of Offset Printing

Offset printing is generally considered to be an environmentally friendly printing method. This is because it uses vegetable-based inks, which are more sustainable and eco-friendly than traditional petroleum-based inks. Additionally, offset printing produces less waste compared to other printing methods, as it does not require the use of printing plates for each individual color. This reduces both material and energy consumption, making offset printing a greener option.

Applications of Offset Printing

Offset printing is widely used in a variety of applications. It is commonly used for the production of newspapers, magazines, and books, as well as promotional materials such as brochures, flyers, and posters. The high-quality and cost-effective nature of offset printing also makes it a popular choice for businesses and organizations looking to create professional marketing materials.

The Future of Offset Printing

While digital printing technology has gained prominence in recent years, offset printing continues to be a vital and relevant printing method. Its ability to produce high-quality prints at a large scale makes it ideal for certain applications. As technology continues to advance, offset printing may undergo further improvements and refinements, ensuring its continued relevance in the printing industry.

Conclusion

The offset printing process is a highly efficient and versatile method for reproducing printed materials. Its rich history, key components, and numerous advantages make it a preferred choice for many businesses and organizations. As technology continues to evolve, the offset printing process is expected to further improve and adapt to the changing needs of the printing industry.

Huida Print-All Technology company is an advanced and professional manufacturer of producing printing plates, mainly sales CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.