In the field of China's newspaper printing production, computer-to-plate technology (CTP) and digital prepress technology are increasingly widely used.

Newspaper Industry CTP: Success Process and Failure Process

The workflow is like the heart of the CTP system. A complete computer-to-plate system should include a set of excellent and applicable digital workflows. When choosing CTP, many users only consider the technical type of CTP equipment, exposure speed, plate cost, etc., but neglect to purchase the overall CTP system and services. Whether it is thermal CTP or photosensitive CTP, can meet production needs.

At present, there are dozens of installed CTPs in China's newspaper industry, but not many of them bring comprehensive benefits to newspapers, and the utilization rate is not high. Some people may cite many reasons but have not carefully considered how to improve their own conditions before taking CTP, such as work plans, layouts, digital proofing, network environment and other factors that affect the effectiveness of CTP. The application of CTP technology not only eliminates the process of film unloading and printing, but also makes pre-press, printing and post-press more closely integrated.

A complete computer-to-plate system solution should have the following elements: digital prepress environment, CTP equipment, plates and workflow. Lack of any one of them will greatly reduce the performance and advantages of direct plate making. The first thing newspapers pursue when adopting CTP is to improve timeliness. It would be a waste if they spend money on expensive equipment but can only solve the timeliness of the first few pages. The workflow of a newspaper computer-to-plate-making system should solve the problem of flexible and automated production from typesetting to plate making, that is, defining the upcoming publishing operations; establishing an imposition plan, customizing the template for the imposition process, and monitoring all operating activities; Help operators and management systems quickly monitor the entire publishing status. It should not only meet the needs of local printing plants, but also meet the needs of overseas printing points to help newspaper printing plants improve productivity and promote sales.

The workflow is a management system that ensures the normal operation of the computer direct plate making process, so that the various equipment, data and information involved in the direct plate making system can operate in a coordinated and smooth manner, and various resources can be fully utilized. Maximizing the system's effectiveness is an indispensable part of a complete CTP system solution, and it is also the part most easily overlooked by users.

Success Stories: Uniflows makes it easy for you

Looking at the workflow adopted by domestic newspapers using CTP systems, the Uniflows reporting process software independently developed by Tsinghua Unigroup can be said to be outstanding. Its professional design is not only open and powerful, but also very convenient to use. It can perform automatic processing quickly and accurately, making the entire process smooth and smooth. At present, several powerful domestic newspaper printing plants have realized its extraordinary inherent qualities: it can better interface with the newspaper's typesetting data, and can integrate newspaper production plans, remote distribution, assembly of large editions, layout description information, The management of plate post-processing equipment and other tasks are all automated, minimizing manual intervention, greatly improving the overall efficiency of newspaper pre-press work, and allowing newspaper users to transition to computer-direct plate-making production in the shortest possible time. Come in the way.

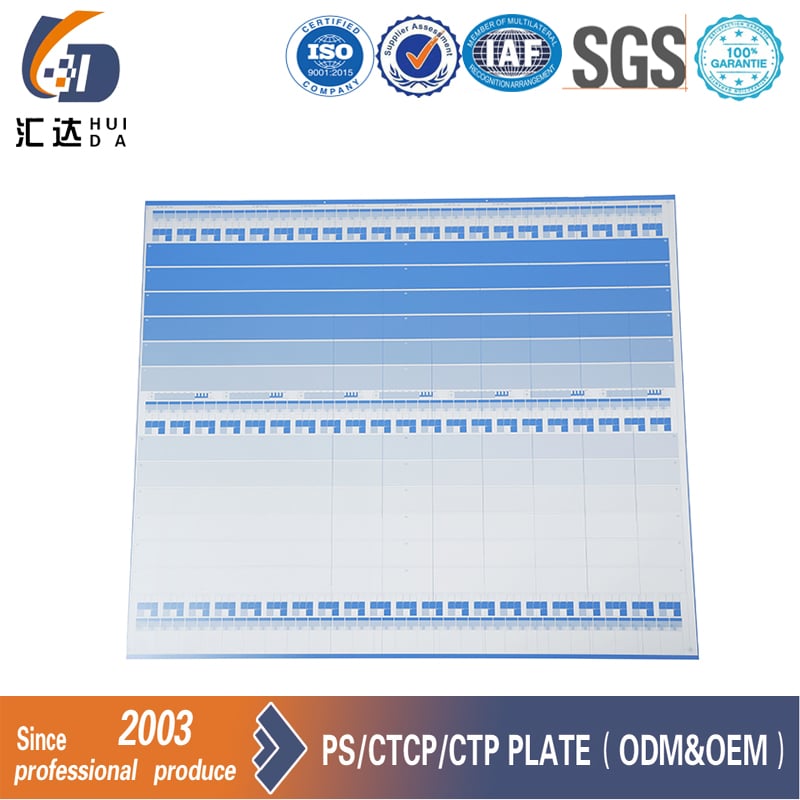

Huida Print-All Technology company is an advanced and professional manufacturer of producing printing plates, mainly sales CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.