CTP plate-making technology is a printing plate directly produced by the machine. CTP technology simplifies the previously complicated plate-making process, and the data is not easy to lose, and the dots are sharp, the reproducibility is good, the plate-making cycle is short, the plate-loading time is short, the entire production cycle of the printed matter is shortened, and the quality of the printed product is also better.

The reason why CTP technology can develop rapidly in the printing field is mainly because of its high speed and high quality, which is very suitable for the high timeliness required by printing. In the traditional plate-making process, it takes a long time for printing and proof. Only the proofs can be printed and printed after being approved by the customer, and the transportation and management of the film may also have an adverse effect on the printing quality. For companies with strong timeliness and the need to print in different places, these defects of traditional technology have become an important factor restricting the development of printing.

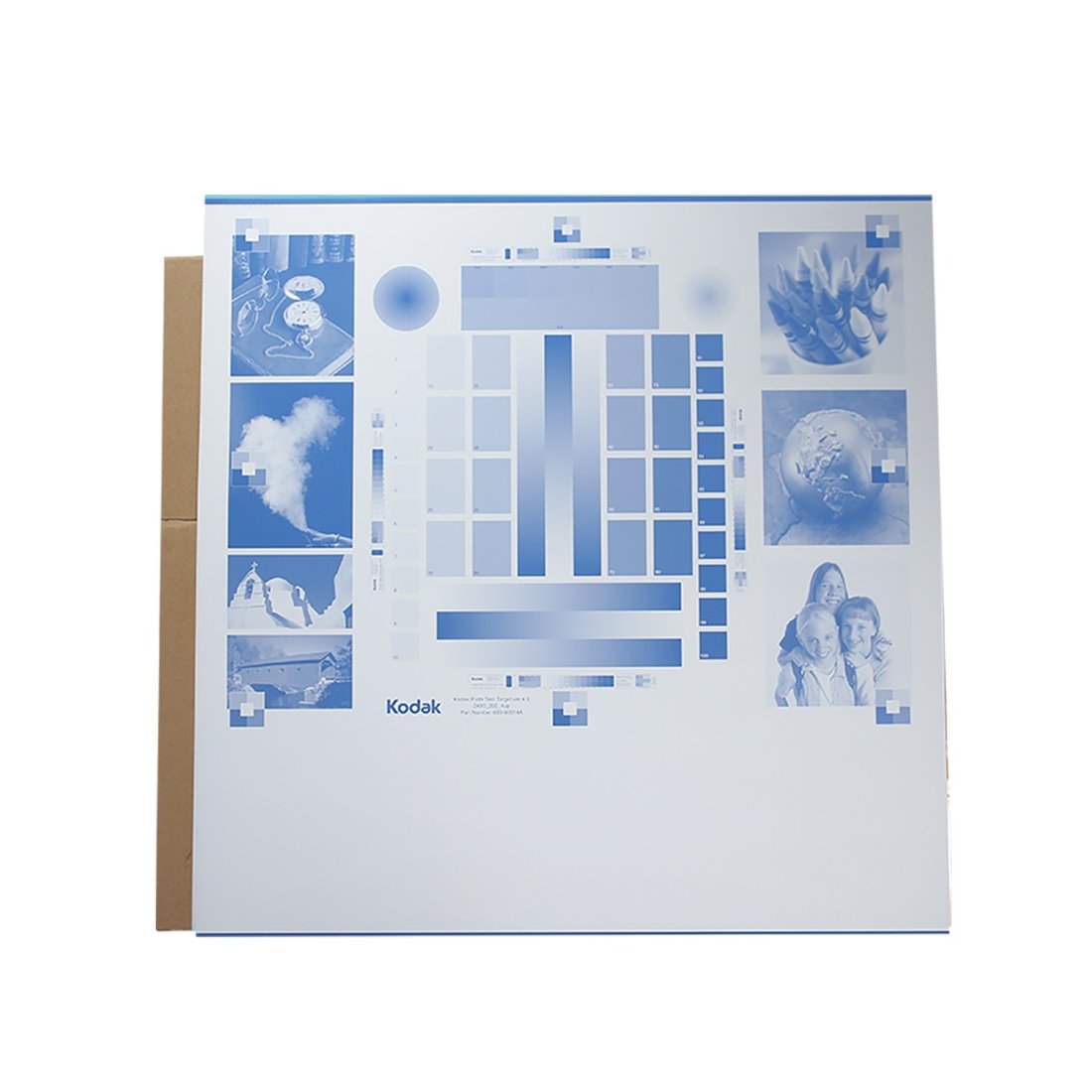

The whole process of the CTP process processes and transmits digital information, and digital proofing technology is also applied. Therefore, the advantages of CTP technology replacing the traditional plate-making process are very obvious. It simplifies the process, saves publishing time, improves the quality of printed products, saves personnel and space, reduces the complexity of equipment maintenance, and reduces environmental pollution. According to estimates, CTP technology can save about 70% of the pre-press work time, and the plate-making time can be shortened by nearly one hour. At the same time, due to the revitalization of the film link, the overprint accuracy and dot quality of color prints are reliably guaranteed, and the error is only about 0.02mm, which solves the problems of labor-consuming man-hours and poor accuracy, and reduces the start-up preparation time. From the perspective of printing effect, the traditional plate-making process can only reproduce 5% to 95% of the dots, while the CTP process can reproduce 2% to 99% of the dots; the products printed with CTP technology have more delicate, richer layers, and more vivid colors; due to the reduction of intermediate links, the accumulation of quality errors is significantly reduced, and the controllability of quality is significantly enhanced. Since the CTP technology reduces the loss of dots on the exposure film and printing plate, it also makes the application of frequency modulation networks possible.

In the past ten years, digital technology in the modern printing field has been mainly used in the pre-press processing stage. With the development of CTP technology, digital technology has begun to set foot in the printing field, while post-press digitalization is still in the undeveloped stage in China. With the further development and application of new technologies. The concepts of diversification, networking, and comprehensive digitization have emerged in the printing field, and CTP technology is just a new printing technology in the printing industry.

Huida Print-All Technology company is an advanced and professional manufacturer of producing printing plates, mainly selling CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.