Offset printing is one of the most popular methods of printing today. It is a process that involves transferring an image from a plate to a rubber blanket and then onto paper or other materials. This type of printing is used for many different types of projects, from business cards to books and magazines. In this article, we will explain offset printing process in details, offset printing step by step, different types of inks used in the offset printing process so that you can really understand the offset printing process.

What is Offset Printing and How Does It Work

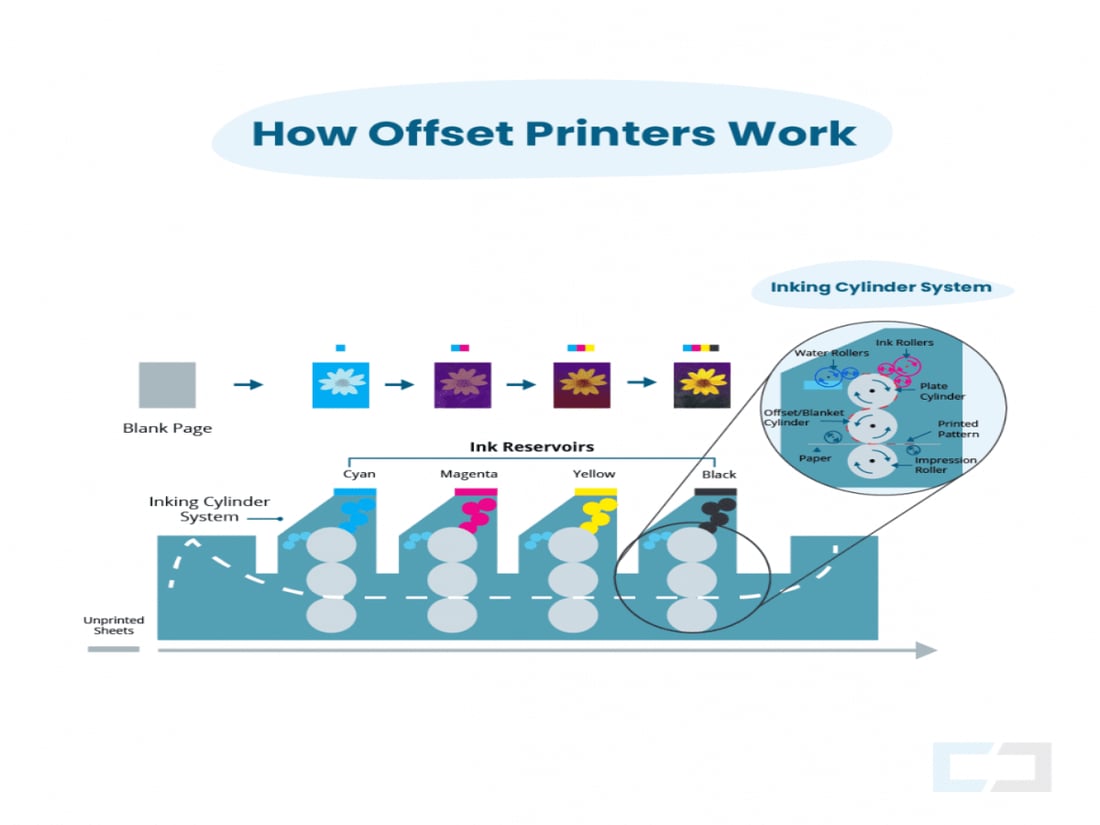

Offset printing is a common printing technique that works by transferring (or "offset") an inked image from a printing plate to a rubber blanket and then to the printing surface.

The offset technique uses a flat (planographic) image carrier in conjunction with the lithographic process that relies on the repulsion of oil and water. While a water roller applies a water-based film to the non-image areas of the image carrier, ink rollers transfer ink to the image areas of the image carrier.

The modern "web" process feeds a big reel of paper in sections, generally for several meters, through a large press machine, which then prints constantly as the paper is fed through.

Today, there are two different versions of the use of offset press. One is that Robert Barclay in England printed on the tin in 1875; the other version is that it was printed on paper by Ira Washington Rubell in the United States in 1904.

Offset Printing Step-by-Step: A Closer Look at the Process

Preparation before Printing

- Printing environment:

Printing is carried out in the printing workshop, and the environmental factors of the printing workshop will have a direct impact on printing. Therefore, it is necessary to prepare the printing environment before printing. We need to standardize the environment before printing. Generally, the temperature is adjusted to 18 ℃ - 24 ℃. The humidity is 60% - 65%, and the light source used is 5000K. After adjusting these environmental factors, we can carry out printing work.

- Preparation of printing plate

Because there are different types of offset printing plates, such as PS, CTP, water-free offset plates, etc., we should select the appropriate printing plate according to the specific situation before printing, and make a good printing plate, the prepared printing plate shall be checked one by one according to the following:

a) Inspection of printing plate surface: Because of the printing plate made with CTP, the image and text cannot be distinguished from the non-image and text, but we can roughly check whether the printing plate has defects, such as wrinkles, holes, etc.

b) Plate positioning inspection: This is mainly to check the punching and bending operation of the printing plate. Incorrect punching will lead to different directions of pictures and texts after plate loading. Therefore, it is very important to check the plate positioning inspection.

- Paper preparation

Because the paper has different paper specifications, the types and sizes of paper are usually different, and various specifications are applicable to different printing. Before printing, we should select different specifications of paper according to the purpose. In addition, before printing, the paper needs to adapt to the printing environment, such as humidifying the paper.

- Ink preparation

Prepare ink before printing.

Ink is mainly composed of pigments, binders and additives,

a) Adjust the ink performance before printing, including

Adjustment of ink viscosity;

Adjustment of ink viscosity;

Adjustment of ink dryness;

b) Ink, add the prepared ink into the ink bucket of the printing machine.

- Preparation of fountain solution

1.The functions of fountain solution in printing include:

Resist the expansion of ink on the printing plate to the blank part of the printing plate;

Add a new hydrophilic salt layer to increase the hydrophilicity of the printing plate;

Reduce the temperature of the printing plate surface;

Before printing, we should prepare the fountain solution, which affects the stability of printing and the effect of finished products.

2. Requirements for fountain solution in printing

It can fully wet the blank part of the printing plate;

Do not cause serious emulsification of ink production and do not change the performance of ink;

It has the ability to decontaminate the blank part of the printing plate and not feel fat;

Do not make the ink diffuse on the wetting liquid surface;

It can maintain the stability of pH value during printing;

Do not corrode the metal parts of the printing machine.

Different Types of Inks Used in the Offset Printing Process

The following section describes the different types of inks in the offset printing process based on the classification of commonly used printing machinery.

According to the classification of printing machines, it can be divided into single-sheet printing ink and rotary offset printing ink. Different printing equipment has different choices for offset printing ink.

- Ink for web offset press

The ink used for web offset press is commonly known as offset rotary ink, which is divided into the following two types:

Infiltration drying type: because the printing speed of newsprint and offset paper web offset press is high and the drying speed of ink is fast, the commonly used ink is mostly infiltration drying type.

Thermosetting ink: In the modern trade web offset press, a drying device is added to the rear half of the printing device. In order to adapt to this production premise, the thermosetting ink is used. This ink is heated in the drying device, and the solvent volatilization in the ink makes the ink film dry quickly. The content of dry oil (such as linseed oil) in the thermosetting ink is small. While the content of petroleum agent is high, and other components are slightly the same as that of single-sheet offset oil ink, the paper used with thermosetting ink is better than the paper used with infiltration drying ink.

- Sheet-fed offset press ink

Offset bright light ink: It is made of synthetic resin, dry vegetable oil, high boiling point alkane oil. Colloidal ink composed of pigments and additives. It is used for printing fine prints such as picture albums and pictures on coated paper by monochrome, two-color or multi-color offset presses. The gloss of the ink is mainly produced by the formation of the film after the binder is dried. The gloss of the ink and the leveling of the ink film are good. It should be able to form a plane attached to the surface of the substrate to reflect the incident light directionally, that is, it has a mirror effect, which requires the binder to stay on the surface of the substrate to a large extent.

Offset resin ink: It is made of synthetic resin, dry vegetable oil, mineral oil, pigment and filler through blending and grinding. Offset resin ink is characterized by low content of vegetable oil and high solvent ratio, usually high boiling point alkanes, which play a role in reducing viscosity in the ink. After the ink is transferred to the paper, this part of solvent will quickly penetrate into the paper fiber under the action of capillary, speeding up the drying speed of the ink, and reducing the scratch of the print.

UV offset printing ink: It uses UV ink for printing in offset printing, which is usually called UV offset printing. UV offset printing ink is a kind of ink that uses the radiation energy of ultraviolet (UV) to make liquid chemicals solidify into an ink film through rapid crosslinking. It requires a UV curing unit in the printer. As a kind of offset printing ink, UV offset printing ink should first be able to print by offset printing, so UV offset printing ink should also have some characteristics of ordinary offset printing ink to meet the requirements of printing suitability.

Offset synthetic paper ink: In the absence of a UV offset press, use the usual four-color printing machine to print special paper such as paperboard, synthetic paper and other inks that are not easy to dry on the surface of the substrate, you need to use offset synthetic paper ink, which can be used to print various non-absorbent printing substrates such as synthetic paper (gold card paper, silver card paper, aluminum foil paper, special paper), and its ink has fast drying on the printed matter, Good adhesion. Because the drying speed of this kind of ink is very fast, when the printing process stops, the ink on the rubber roller should be cleaned in time to prevent the ink from scaling and drying.

Offset printing is a great way to create high-quality print projects with a professional look and feel. With offset printing, you can produce large quantities of prints quickly and cost-effectively. It also offers superior color accuracy, resulting in vibrant prints that really stand out. Whether you’re creating brochures, posters, business cards or anything else, offset printing is an ideal solution for producing quality prints that will last.

Huida Print-All Technology company, as an advanced and professional manufacturer of producing printing plate, mainly sales CTP, CTCP and PS plates as well as offering ODM/OEMs especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.