The different printing methods, it is divided into four methods: offset (lithographic) printing, letterpress printing, gravure printing, and screen printing.

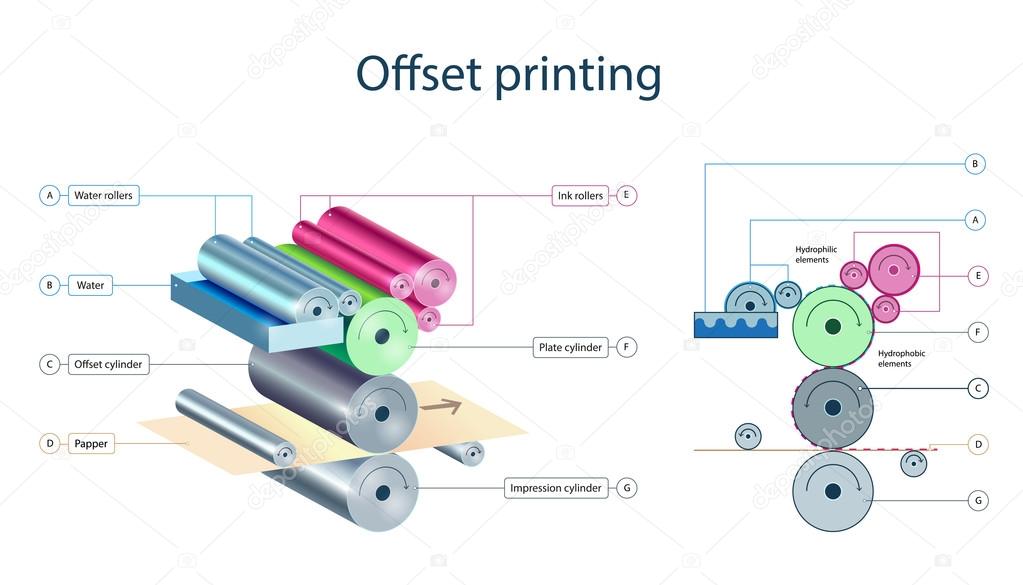

Offset (Lithographic) Printing

What is Offset (Lithographic) Printing?

Offset printing is a common printing technique in which the inked image is transferred (or "offset") from a plate to a rubber blanket and then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier. Ink rollers transfer ink to the image areas of the image carrier, while a water roller applies a water-based film to the non-image areas.

How to Do Offset (Lithographic) Printing?

First, the water supply device of the printing plate parts supplies water to the non-graphic part of the printing plate, to protect the non-graphic part of the printing plate from being wetted by ink. Ink is supplied to the printing plate by the ink supply device of the printing part. Since the non-graphic part of the printing plate is protected by water, the ink can only be supplied to the graphic part of the printing plate.

Finally, the ink of the printing plate is transferred to the blanket, and then the pressure between the blanket cylinder and the impression cylinder is used to transfer the ink on the blanket to the substrate to complete one printing. Therefore, lithography is a process. an indirect printing method.

Offset Printing Feature

It offers excellent photographic quality.

It can be printed on all kinds of papers.

Resists the use of special inks.

Paper sizes can be larger than in digital printing.

Allows you to print large runs with lower costs.

For large runs, the offset printing model is much faster.

Allows a faithful duplication of image detail.

It is faster as there is less time to prepare the plates, compared to printing systems such as gravure or flexography.

The PS plate and CTP plate are both offset printing plates.

China Positive PS Plate for Offset Printing (Available Custom Sizes)

Positive Thermal CTP Plate | Offset Plates (Available Custom Sizes)

Letterpress Printing

What is Letterpress Printing?

The graphic part of letterpress printing is higher than the non-graphical part, and the ink transfer roller is used to evenly apply the ink to the printing plate, and then print. Because the non-graphic part is concave, it cannot be inked.

Letterpress Printing Features

The ink expressiveness is about 90%, and the color tone is rich. Strong color reproduction. The layout is durable. The number of prints is huge. A wide range of paper is used, and materials other than paper can also be printed.

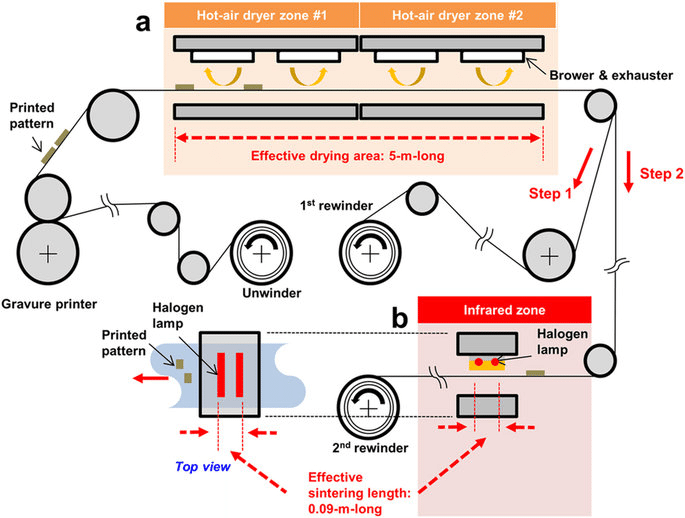

Gravure Printing

What is Gravure Printing?

The non-pattern part of gravure printing is higher than the graphic part, that is to say, the graphic part of gravure printing is composed of N concave net pits, and the plate roll of gravure printing is directly inked, and then there is a squeegee to scrape it. Pure non-graphic ink, because the ink in the graphic part is hidden in the concave mesh pit and will not be scraped off, so it can be directly printed after being pressed by the pressure roller.

Gravure Printing Features

Anti-counterfeiting, gravure printing uses the pits carved according to the original drawings to carry ink, the thickness of the lines and the thickness of the ink can be arbitrarily controlled during the engraving, and it is not easy to be imitated and forged, especially the depth of the ink pits, according to the printing. The possibility of realistic engraving of good graphics is very small.

Screen Printing

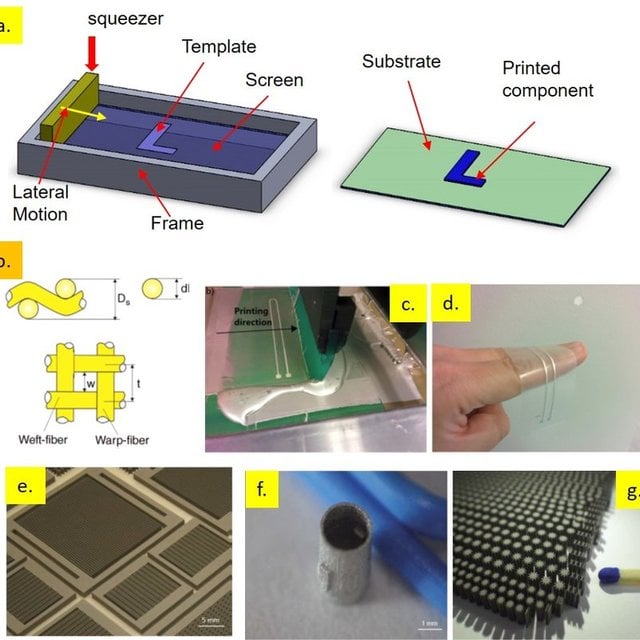

What is Screen Printing?

Printing is done by using the basic principle that the mesh of the graphic part of the screen-printing plate is transparent to the ink, and the mesh of the non-graphic part is impermeable to the ink. When printing, pour ink on one end of the screen-printing plate, apply a certain pressure to the ink part of the screen-printing plate with a scraper, and move to the other end of the screen printing plate at the same time. The ink is squeezed onto the substrate by the scraper from the mesh of the graphic part during the movement.

Application for Different Printing

Plastic printing: vinyl toys, school bags, plastic bags, etc.

Woodwork Printing: Crafts -- Lacquerware, Wooden Crafts, Toys

Metal products printing: metal cylinders, metal utensils, metal products

Glass, ceramic products printing: glass - mirrors, glass plates, cups, bottles, etc.