Understanding the Offset Printing Process

Offset printing is a widely used printing technique that involves transferring an image from a plate to a rubber blanket, and then onto the desired printing surface. It is a cost-effective and high-quality method used to produce large quantities of printed materials. In this article, we will delve into the key aspects of offset printing and explore its advantages and applications.

The Key Components of Offset Printing

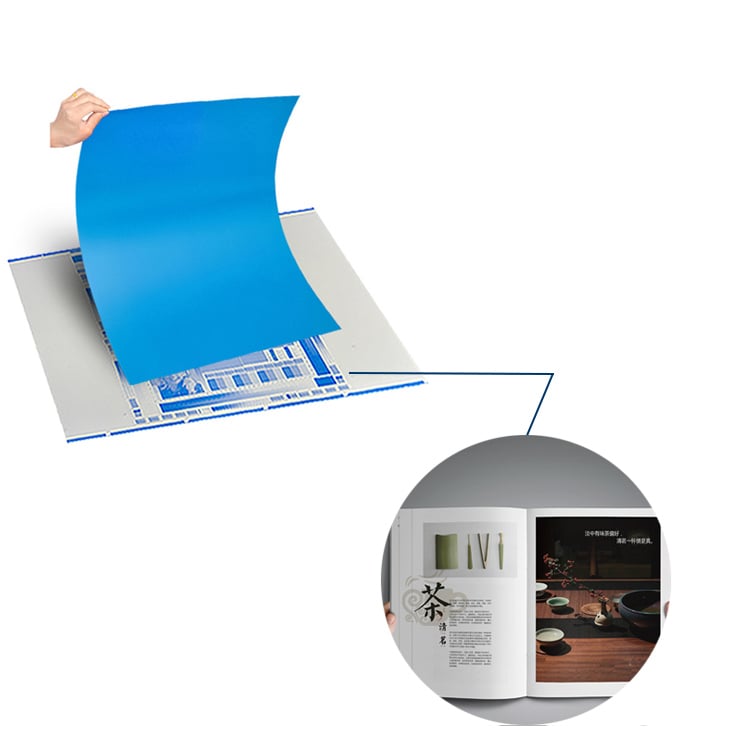

Offset printing involves several essential components that work together to produce exceptional print quality. These components include the plate, blanket, ink, and printing press. The plate is typically made of aluminum and carries the image to be printed. The blanket acts as an intermediary, transferring the inked image from the plate to the printing surface. High-quality inks are used to ensure vibrant and accurate color reproduction. The printing press is the machine that brings all these components together to produce the final printed material.

The Advantages of Offset Printing

Offset printing offers numerous advantages over other printing methods. Firstly, it allows for consistent and high-quality results, thanks to the precise image transfer process. The use of separate plates for each color also ensures accurate color reproduction. Additionally, offset printing can handle a wide range of printing surfaces, including paper, cardboard, and even plastic. It is also highly cost-effective for large print runs, making it the preferred choice for bulk printing projects.

Applications of Offset Printing

Offset printing finds extensive application in various industries. It is commonly used for printing books, magazines, brochures, and newspapers. Its ability to reproduce fine details and vibrant colors makes it ideal for marketing materials, such as flyers and posters. Offset printing is also used for packaging materials, such as boxes and labels. Its versatility and consistent results have made it a popular choice for a wide range of printing needs.

Offset Printing vs. Digital Printing

While offset printing remains a dominant printing method, digital printing has gained traction in recent years. Digital printing offers advantages such as faster turnaround times and variable data printing capabilities. However, offset printing still holds several advantages over digital printing. It offers superior color quality, especially for large print runs. Offset printing also allows for a wider range of substrates and finishes, making it more versatile than digital printing in certain applications.

The Environmental Impact of Offset Printing

As concerns about the environment continue to grow, it is essential to consider the environmental impact of printing methods. Offset printing has made significant strides in reducing its environmental footprint. It uses vegetable-based inks that are more environmentally friendly than traditional petroleum-based inks. Additionally, advances in plate-making technology have reduced water and chemical usage. Offset printing also allows for efficient paper usage, minimizing waste.

Choosing the Right Printing Method

When deciding between offset printing and other methods, it is crucial to consider your specific printing needs. Offset printing is ideal for large print runs and projects that require vibrant colors and detailed images. If you have a smaller print run or require variable data printing, digital printing may be a better choice. Consulting with a printing expert can help you determine the most suitable printing method for your specific requirements.

offset printing definition and Glossary

Here are some key terms related to offset printing:

- Plate: The aluminum sheet carrying the image to be printed.

- Blanket: The rubber blanket that transfers the inked image from the plate to the printing surface.

- Ink: High-quality inks used for accurate color reproduction.

- Printing Press: The machine that brings together the plate, blanket, and ink to produce the final printed material.

- Color Separation: The process of separating an image into different color components for printing.

Conclusion

Offset printing is a versatile and cost-effective printing method that offers consistent and high-quality results. Its ability to handle a wide range of printing surfaces and produce vibrant colors makes it a preferred choice for various printing needs. By understanding the offset printing definition and its key components, you can make informed decisions when it comes to choosing the right printing method for your projects.

Huida Print-All Technology company is an advanced and professional manufacturer of producing printing plates, mainly sales CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.