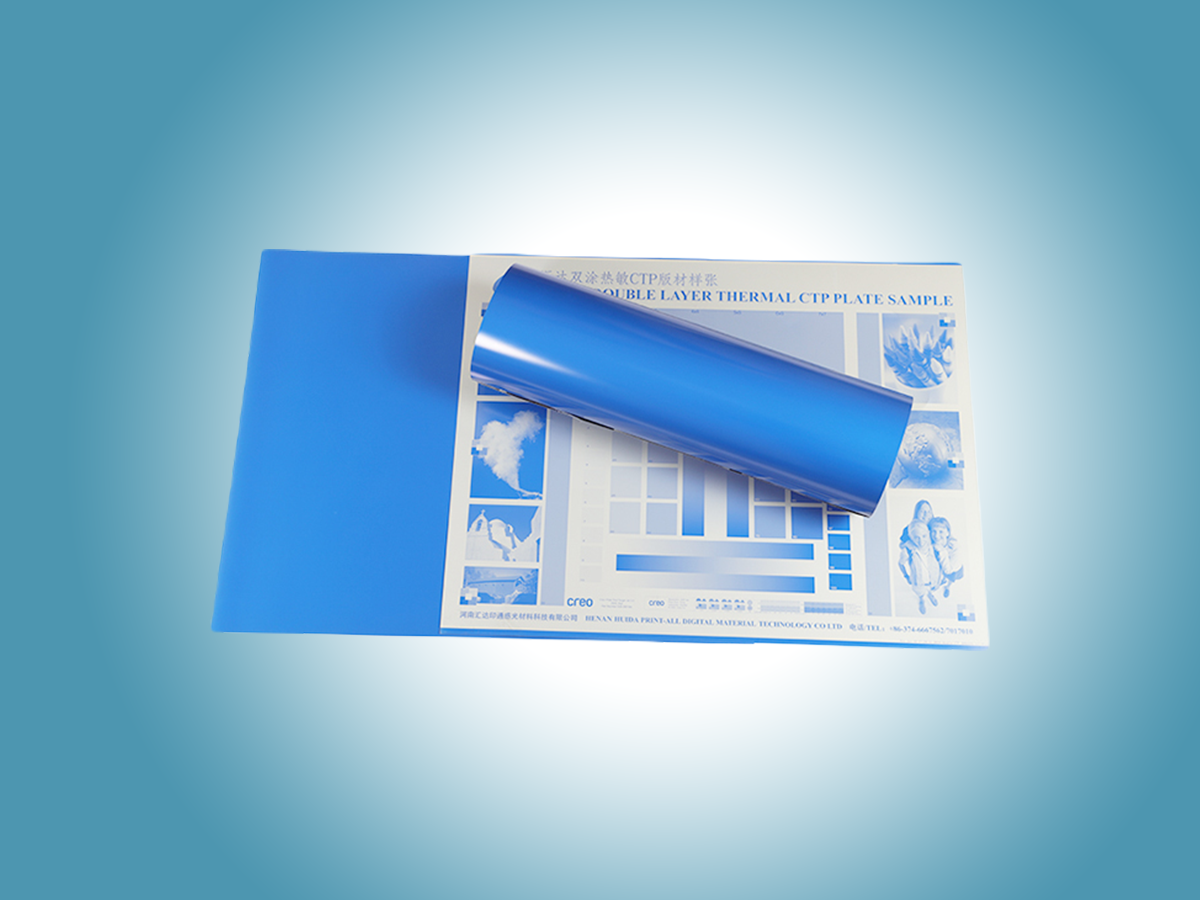

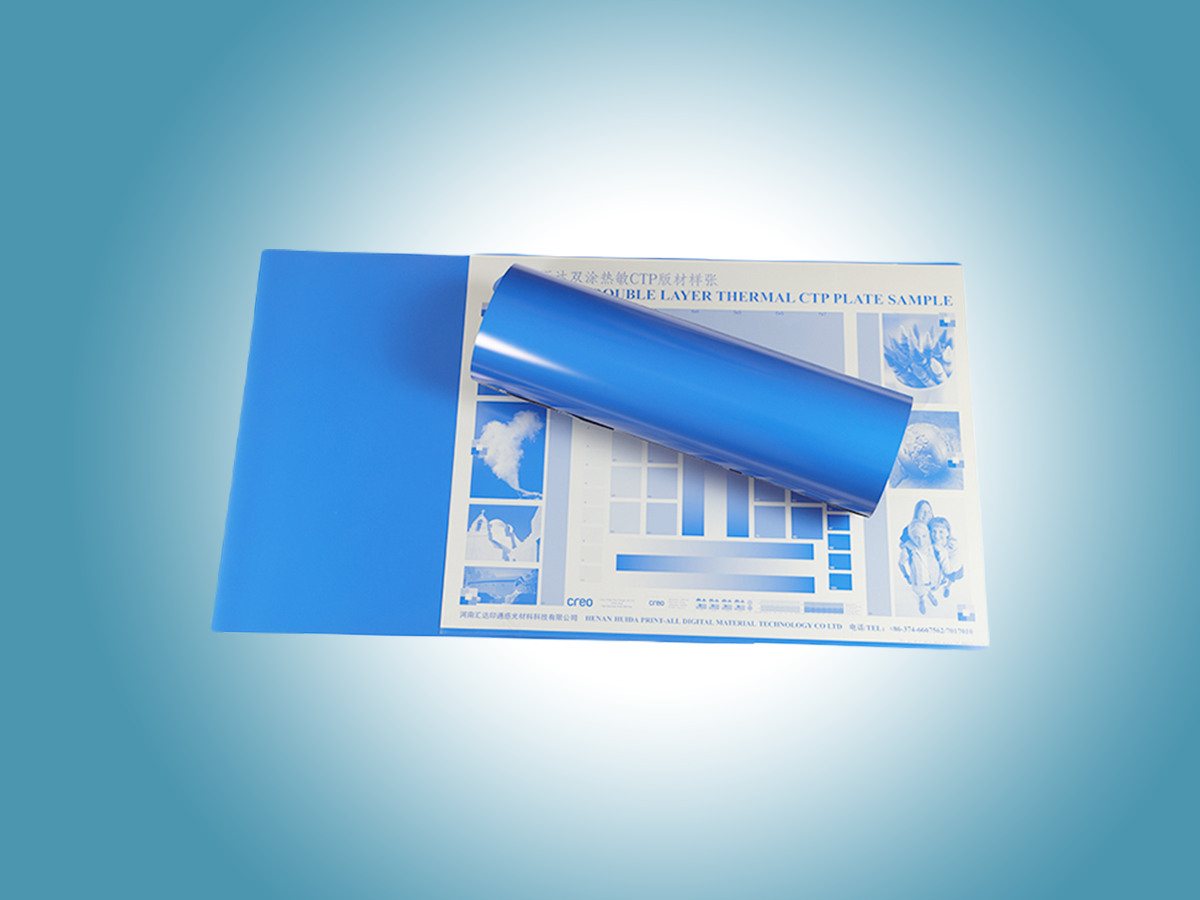

Double Layer Thermal CTP Plate | Offset Plates (Available Custom Sizes)

The thermal CTP plate has a wide selection of technologies such as heat-dissolving type, thermal etching type, photo-etching type, thermal cross-linking type, and degradable type. The heat-sensitive printing plate has both direct imaging and through the masking layer. Indirect imaging.

Our Strength

Henan Huida Print-All Technology Co., Ltd. found in 2003, with almost 20 years of development, has become the largest ctp plate maker in China.

Main products including digital photosensitive plates and conventional plates:

1. Positive Conventional PS Plate

2. Positive Thermal CTP Plate

3. Positive CTCP Plate

4. Double Layer Thermal CTP Plate

The ctp plate is widely used in the printing industry, like newspaper printing, cans printing, electronic printing, etc.

Get a Quote

Send your message to us by the below button (SEND INQUIRY):

For better quotations, include:

- A self-introduction

- Special requests, if any

We will reply to you within 24 hours!!!

UV Ink Compatiable Thermal CTP Plate

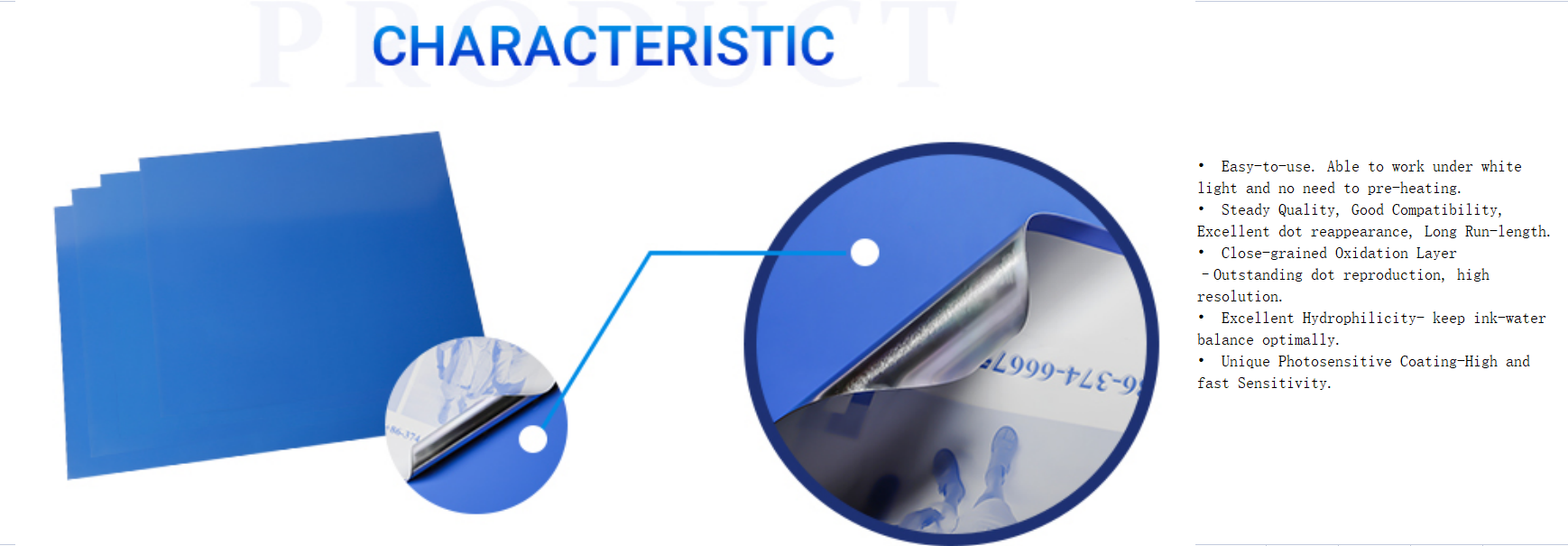

1.updated ctp plate with the latest unique deep bluephotosensitive formula and the advanced thermal plate technology, which is specifically designed for cost-conscious printers for orinary and UV ink printing, who need long run lengths with high-performance press quality.

2.the widest developing tolerance and adaptability, the easiest use for end-users, no machine adjustment, no any ash or dot loss.

|

Style |

UV Ink Compatiable Thermal CTP Plate |

|

Gauge |

0.15/ 0.20/ 0.25/0.30mm ( 0.20/0.25mm customized production ) |

|

Max. Size |

1650*1350mm |

|

Coating |

Deep Shinny Blue |

|

Spectral Sensitivity |

830nm |

|

Exposure Engery |

110-120 mj/cm2 |

|

Run Length |

UVink 60000 copies,ordinary ink 200,000copies,actualrun length depends on processing and printing quality control andconditions |

|

Application Type |

Extremly Long Run without Baking for UV Ink Printing, commercial printing, packaging printing |

|

Compatible Platesetter |

All the common thermal platesetter brands in the market |

|

Protection Gum |

recommended to use 140G protection gum |

|

Developing Condition |

Developer: Kodak Gold Star Premium and Huida developer best, other brands workable except Fuji developer |

|

Developing Temperature : 23-28℃ |

|

|

Developing Time: 25-35s |

|

|

Replenishment Rate: 60 ml/sqm |

|

|

Reference Working Condition |

Kodak platesetter & Kodak GS developer 10W 200rpm 23-24S,25-30S 6-8W 200rpm 22-23S, 30S 12W, 150rpm 20-22S, 30S |

|

Baking Condition |

No need to bake |

|

Day Light Tolerance |

2 hours |

|

Shelf life& Storage Conditions |

18 months, store plates flat in their packaging, 10-25 ℃ ,with RH 40%--60%, stock height less 1.5m. Away from excessive heat, high humidity, Anti-acid &alkali |

|

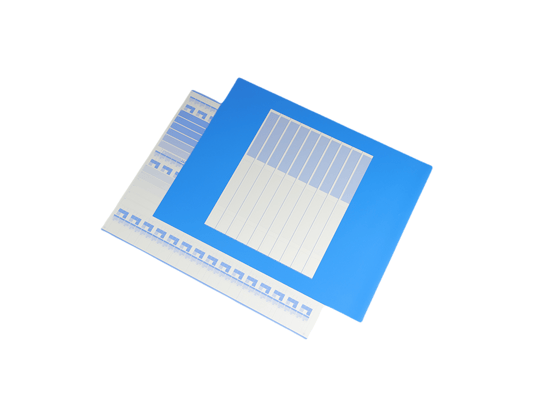

Package |

Strong Safe Seaworthy Package: 100sheets for 0.15mm, 50sheets for 0.30mm, wrapped by a black photo protective paper, then put in a carton box, finally 20-60boxes on a ply-wood pallet, outer covered by cardboard and wrapped plastic film |

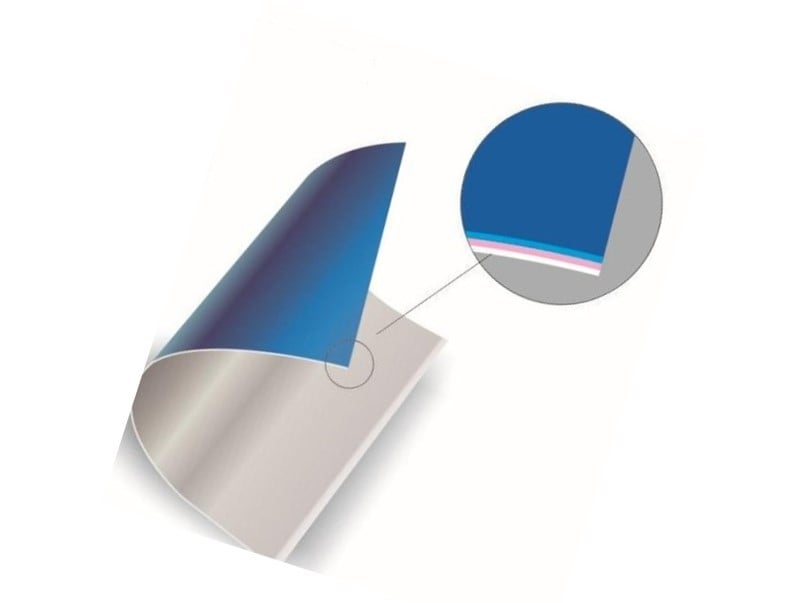

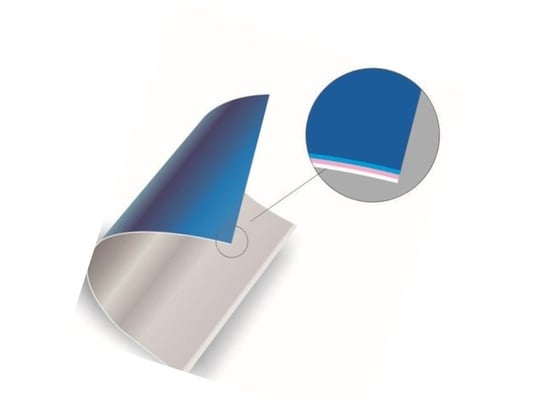

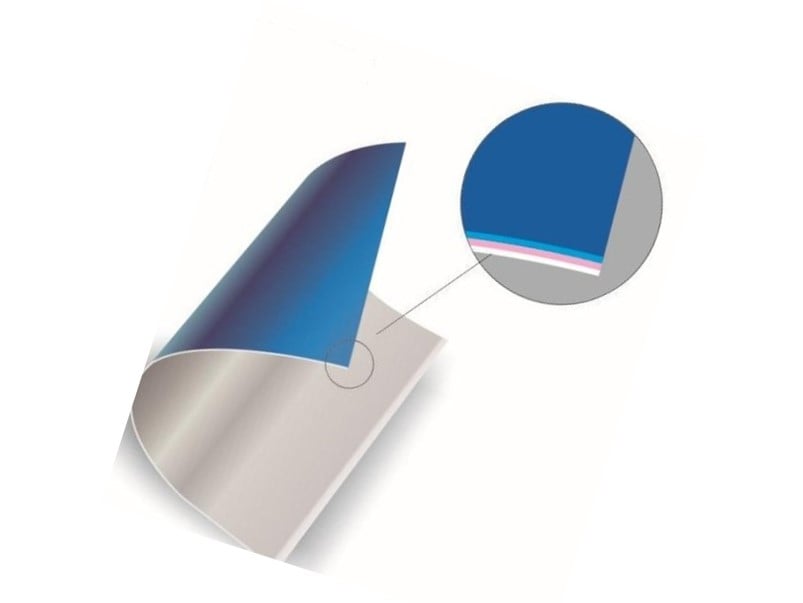

Double Layer Anti-UV Ink Thermal CTP Plate

|

Product Type |

Double Layer Anti-UV Ink Thermal CTP Plate |

|

Compatible Platesetter |

All brands ctp platesetters |

|

Plate Thickness |

0.15/0.20/0.25/0.30/0.40mm |

|

Maximum Coil Width |

1350mm |

|

Spectral Sensitivity |

830nm |

|

Exposure Energy |

110-120mj/c㎡ |

|

Developing Condition |

23-28℃, 25-35S |

|

Safe-light |

2 hours under white light |

|

Resolution |

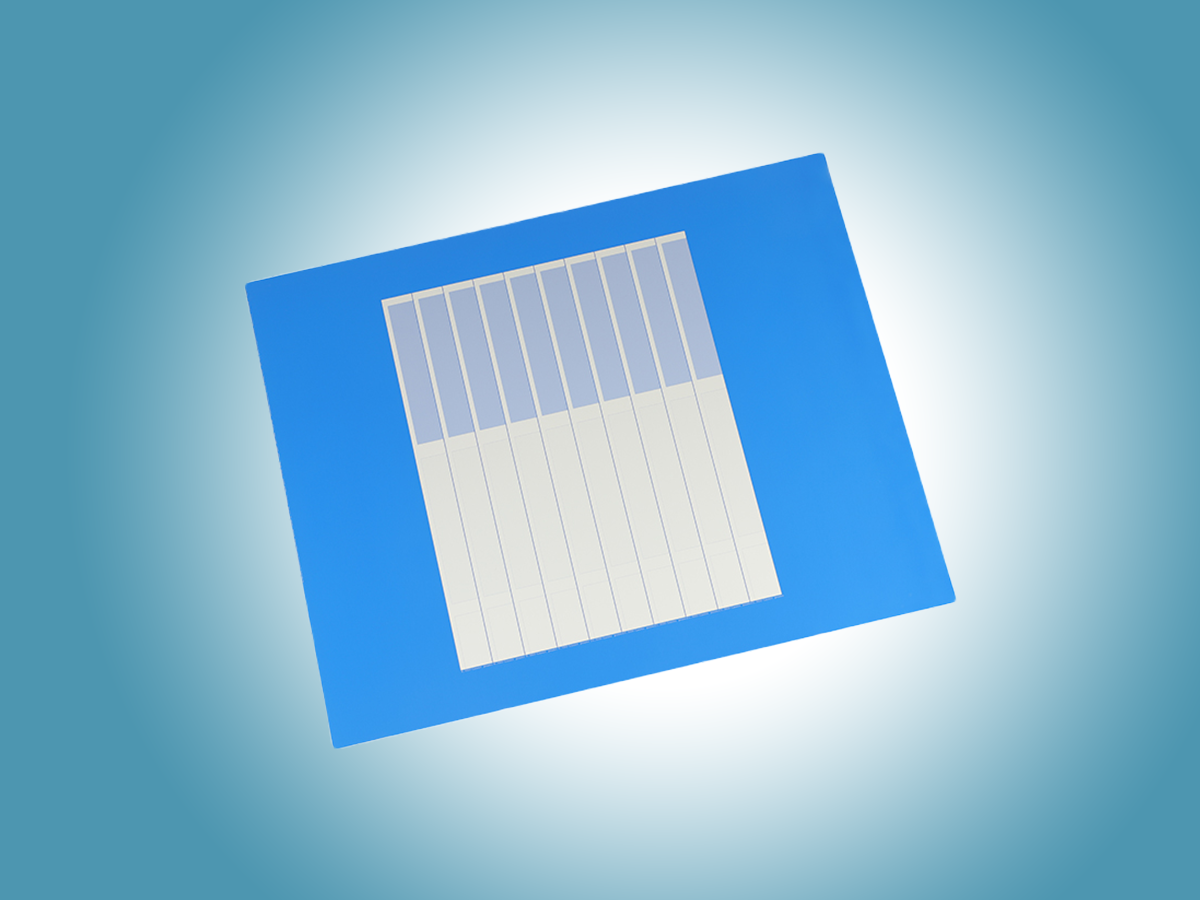

1-99% at 200lpi |

|

Run Length |

100000-200000(UV lnk) 150000-250000(Ordinary lnk) *Run Length varies with its printing conditions and imaging content, including paper,ink) |

|

Shelf Life |

18 Months |

|

Storage Conditions |

Temperature 10-25℃, 40%-60% humidity Keep away from sunlight and humidity. Pack height<1.5 meters

|

Inquiry

- Выбор выделенного элемента приводит к полному обновлению страницы.