The development of thermal CTP and violet laser CTP has always been controversial, and currently, CTP technology is mostly divided into the two categories of thermal and photosensitive.

What is Thermal CTP & Features

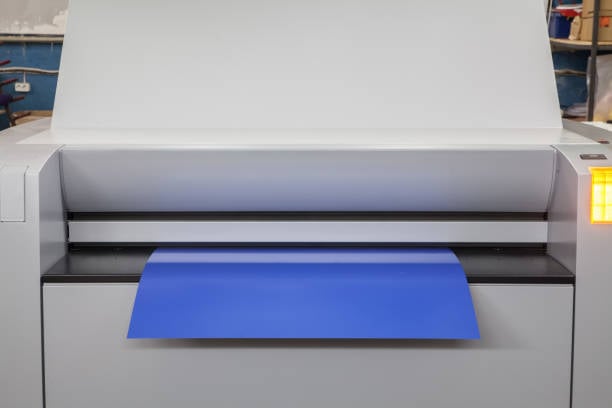

Modern printing presses that use thermal computer to plate (CTP) imaging technology have superseded previous computer to film (CTF) technology. Components of the CTP platesetter as well as the processing fluid must keep a constant temperature in order to reliably provide the highest-quality imaging.

- Highest quality output with a line rate of more than 300 lines per inch

- Processing during the day

- Numerous options for platesetters that are simpler to fix at local agents

- The average CTP run lasts between 100,000 and 20,000 impressions, however when thermal plates are baked, they can last up to one million impressions.

What's the Features of Photosensitive CTP?

-

Faster

People who are knowledgeable in physics are aware that violet lasers have wavelengths of 400 nm. The shorter the wavelength, the more energetic the light is. By using a violet laser light source, the plate remains in place for a brief period of time while also supplying enough energy to drive the interaction of the film with the plate, increasing the speed of imaging as a result.

-

Increased Precision

Additionally, from a physics perspective, the shorter the laser spot's spectrum, the smaller it is, allowing you to scan the smallest dots on the plate.

-

A more comfortable working environment

Since violet digital plates don't react in red or green, the violet laser CTP device can instead employ a yellow safety lamp to give the operator a brighter working environment and make operations easier.

-

Live Longer, Spend More Money

Maker of lasers for the maintenance of the common green laser-powered violet laser light source. The violet laser CTP's actual product life is longer than that of other laser sources due to the operational characteristics of violet, which are: laser will not simply be triggered in real-time imaging, unlike other lasers as the laser power should start at the same time we should.

Many people believe that heat is an expensive technique made for high-volume printing, according to an article that was previously published in a renowned international magazine. This is a misconception of the thermal CTP, in actuality.

Misinterpreting the First: Thermal Ctp is Costly

The most cost-effective technology for creating digital plates has been dubbed violet laser imaging. The cost that the user will actually have to pay for the total is not taken into account; this is simply based on the conclusion of the violet laser CTP's price. Similar to how a cheap car that costs $1,000 does not ensure that its subsequent costs will be similarly minimal. Selecting CTP purely on the basis of hardware cost is illogical.

The total cost of printing can be decreased by using thermal CTP to cut several processing expenses. Thermal CTP lasers, for instance, are up to 100 times less expensive than the least expensive visible laser source. In order to save money on facility costs and to create better working conditions, thermal CTPs do not need darkrooms or safety lighting. Additionally, some CTP versions of visible light are less dependable than thermal storage, which might reduce the cost of job reprint printing. Implants with thermosensitive plates require less care than CTP plates with silver versions, thermal diodes last longer than visible light lasers, and losses from laser aborting are minimal.

Misinterpreting the Second: The Plate is Pricey and Has a Reduced Heat Sensitivity

In actuality, there are more vendors selling heat plates than violet lasers right now. There are only three or four violet laser versions produced by the manufacturer, compared to up to 28 thermal versions( maybe inaccurate data). Because there are so many producers, we have reason to think that the cost of thermal plates will keep dropping.

Misinterpreting the Third: Solely Using Thermal Ctp to Print an Extended Version of the Live Printing Plant

Violet lasers are targeted for printers that print fewer pages, but thermal CTPs can still be used in this market. Small printing lacks thorough testing equipment, leading the majority of them to mimic CTP model purchases of many units, making it challenging for them to independently decide on CTP's course of action. They have the option of heat CTP or violet laser CTP.

According to certain polls, more than 10% of installed CTPs are inactive. It is startling that 10% of CTPs are idle considering that the majority of CTP devices are placed in less than five years. It goes without saying that some printers purchase CTP systems that are difficult to use, expensive, or outdated and have little market value. Scalability and ease of reselling are advantages of thermal CTP systems. The sales ratio of thermal CTP to violet laser CTP is 3:1. According to the data, sales of thermal CTP plate material exceeded those of visible plate by more than 50%.

Misinterpreting the Forth: Thermal Ctp and Violet Laser Ctp Are of Equal Grade

In production situations, FM random screening is possible because to thermal square dot technology. Random screening offers several benefits, but the most intriguing one is that the color of the random screen printing is rarely impacted by the color of the paper, allowing you to print on cardboard and less expensive or bleached paper. The thermal CTP spot diameter can be as small as 10 micrometers, allowing for the printing of extremely fine print. With few changes to the press, thermal CTP offers improved process control and quicker print preparation. Thermal CTP generally provides consistent quality, vivid colors, and crisp dots. Printers who wish to boost output and prevail in the intense competition can go for thermal CTP.

Now that you are aware of this fact, get a quote for the best products and services from HUIDA Offset Printing to meet all of your printing needs for your forthcoming project!