Do you have a brochure, poster, or some other kind of need-to-print product you want to get to the press? Once you do, you need to figure out which print method is the best for your job. That's where the question about whether to choose digital vs. offset printing will arise.

A precise print method, you might say? What's the difference between these options?

So, you start to look up the process, or you go straight to the print shop. They ask- how do you want this printed?

Um, through the press?

Okay, sure, but which kind of press, digital or offset? They even show you some samples to demonstrate the differences in printing techniques.

If you aren't an expert, you might not be able to tell the difference, especially at first glance.

Before you get to that question and stand there bewildered, we have gone ahead and done a little work for you.

In sum:

- Offset printing is the original, durable, and time-tested option. It's best for large to massive, cost-effective print runs. Plus, it guarantees excellent color options and the broadest range of surface print materials.

- Digital printing is a lightweight, cost-effective option for smaller quantity print runs. Its rapid turnaround and slick versatility make it hard to beat. Not to mention, new, innovative technology is continually advancing.

Printing Technology: from lithography to newer, multi-function processes

From as early as 1875, offset printing dominated the print industry. It was and still is a method for printing on tin such as for antique tin litho toys like vintage toy trains. Printer makers and users have been honing and optimizing this process for a long time. The timeless durability and the range of available print styles and customizations have established it as one of today's standard print methods.

Yet, a more lightweight, versatile, and speedy printing method exists. Large-scale, commercial digital printers work much like the printer you might have at home. These digital presses use laser or inkjet technology. It's a hands-off machine that makes it easy to get a last-minute project thrown together.

One of the added benefits of digital printers is their ability to cut, collate, and even bind — incredible time-savers.

But how do these processes work? Can job run-time or quantity make a difference? Or do the final print jobs even look different? Let's see.

What is offset printing?

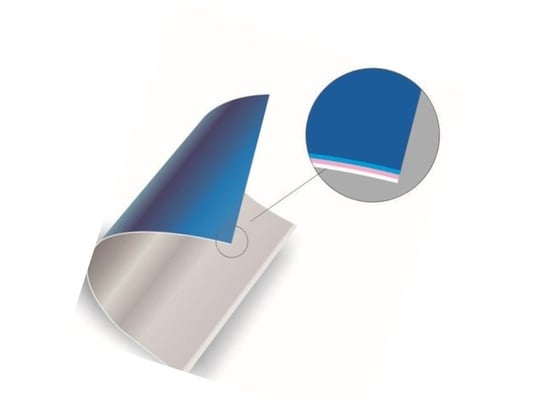

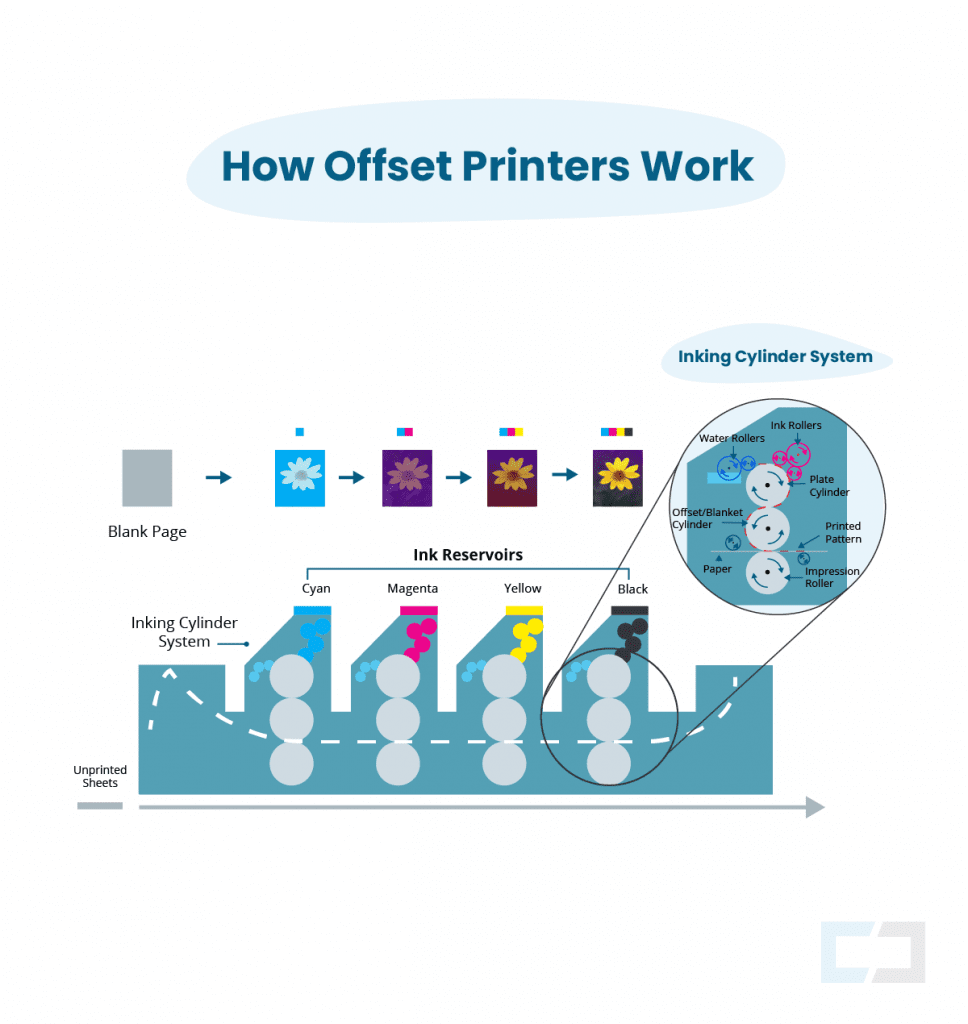

Offset printers layer ink one by one to achieve high-quality color with a distinctive inking cylinder system.

The iconic vision of newspapers hot off those spinning rolls is what we're taking apart for you. That's offset printing.

What has to happen first is an initial, manual step in the prepress production. (Prepress means before the print or publishing process.) That initial setup includes:

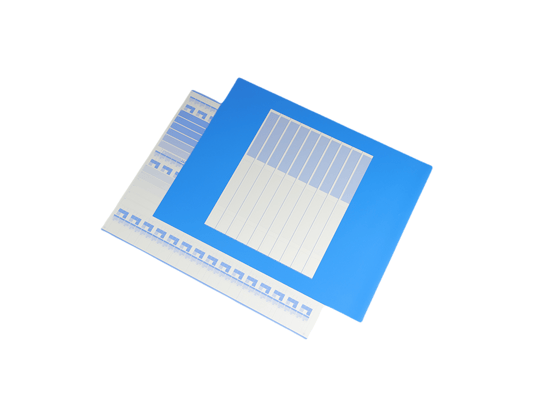

- Transferring or burning the print project (usually a digital file) onto four large, thin aluminum plates. One plate is prepared for each of the 4 CMYK colors (cyan, magenta, yellow and black).

- Wrapping the flexible plates, now with the imprinted design, around the plate cylinder.

The entire reason offset printing goes by offset printing is because of this: The image on the aluminum plate cylinder transfers or “offsets” to a second rubber blanketed cylinder. (Also referred to as the “blanket.”)

Like the gears of a clock, all the cylinders move together as a team:

- Each spin of the plate cylinder gives a swipe of fresh ink onto the design

- The inked design transfers (offsets) to the blanket cylinder

- The ink presses directly onto the printing surface from the (paper, stock, etc.)

This entire process produces sharper, cleaner images because the rubber gently and smoothly conforms to the surface texture of the print material. The process is well-suited for the widest range of paper stocks. It also provides the highest control over the quality of color printing, as the paper absorbs the ink.

With the initial setup, there is a bit more time and labor included in this process. Even still, once the press is ready for action, it works fast and spits out high-quality printed pages.

It’s an affordable option for large run projects like books, magazines, catalogs, and more.

In short: Offset printing is rolling a wet-inked design directly onto a surface. It needs time to dry before touching.

What is digital printing?

Digital printing is much more user-friendly.

Remember the offset printing prepress setup? That entire step disappears.

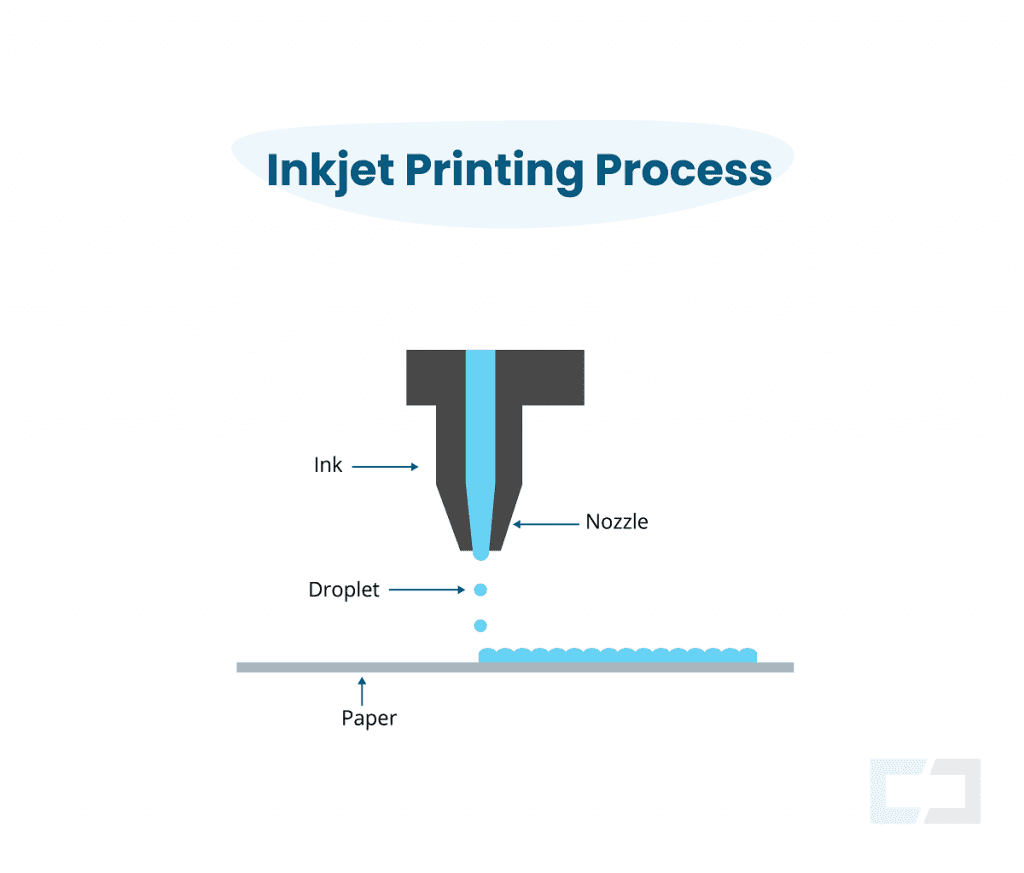

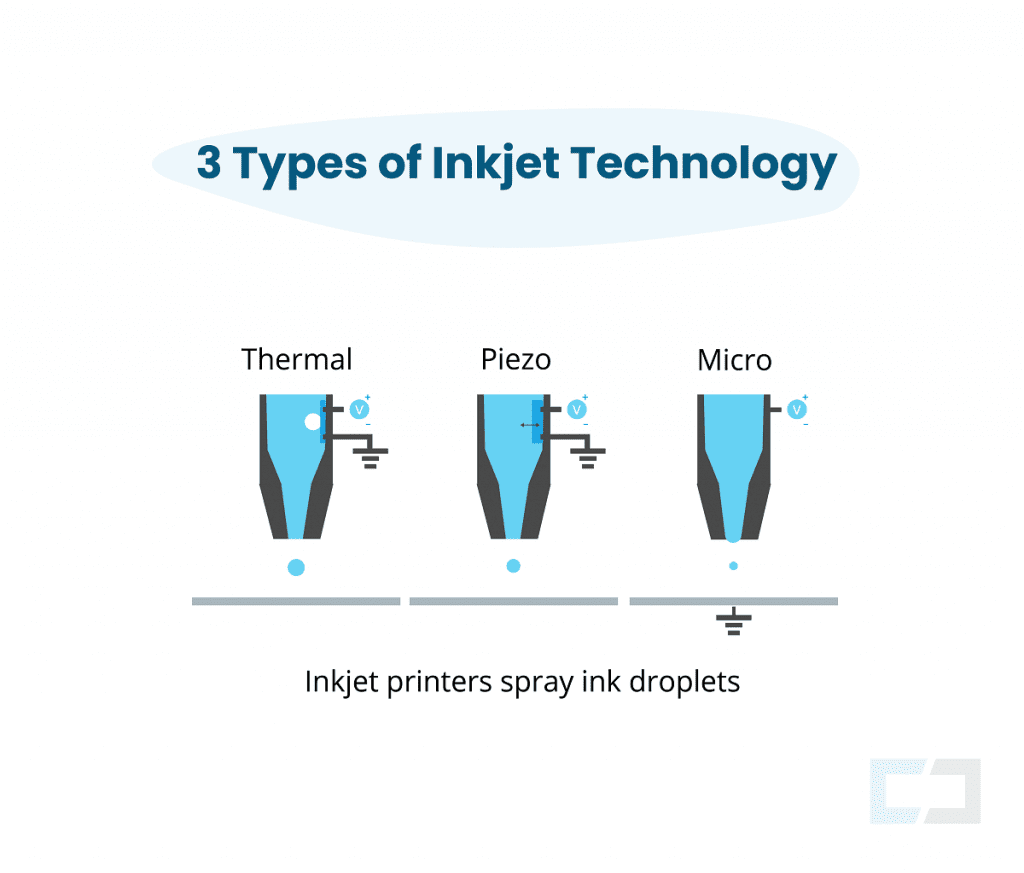

Instead, these printers use one of two methods: inkjet or laser. The processes inside the machine are a bit more technical. In general, it includes laying the color directly on top of the paper with thousands of dots.

The inkjet spits out targeted, tinier-than-a-pin-prick of color ink drops.

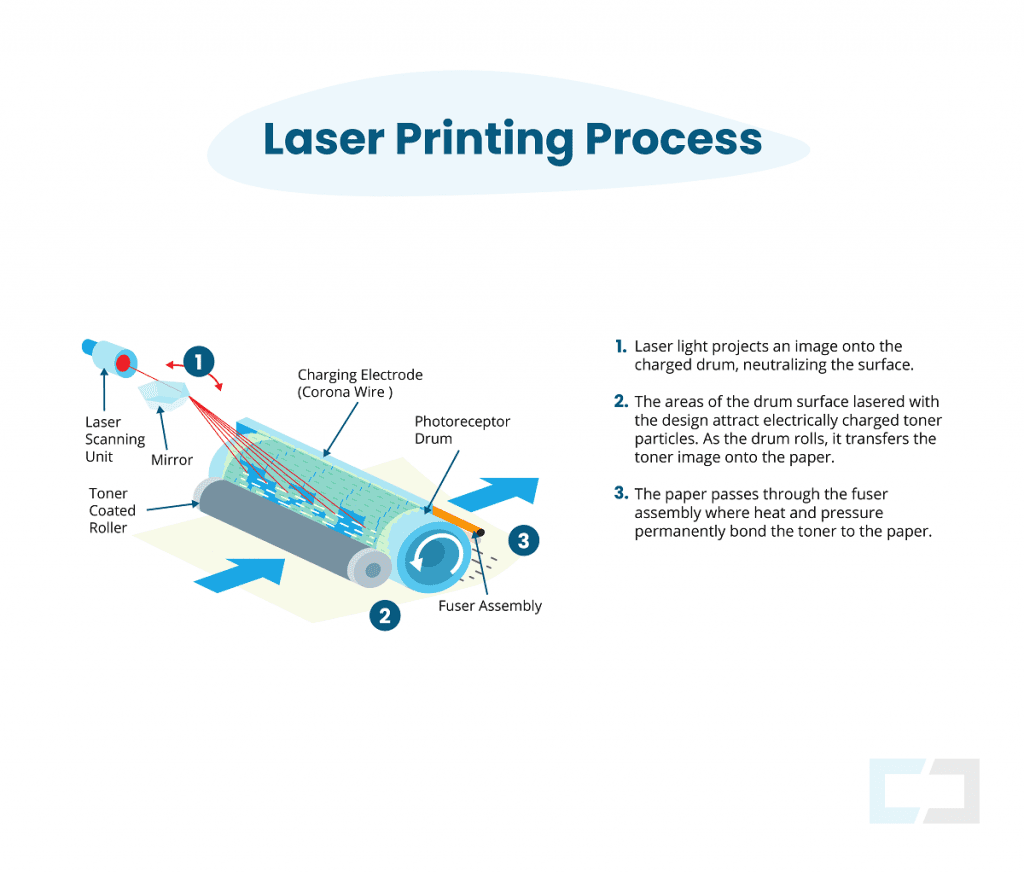

While the laser printer is a tad more complicated. It beams a laser that neutralizes charges located on electrostatic rollers (“drums”). Those neutralized areas pick up toner and deposit the toner on paper.

Either way, the operation takes place within the machine and requires minimal setup.

If you've ever observed or used a personal home printer, you get the gist.

There isn't a prepress plate preparation for this type of printing. The benefit to that is a quicker turnaround and generally lower cost. However, the level of image detail decreases, and color precision is less accurate.

In short: Digital printing is a combination of thousands of tiny dots of toner cooked onto a material. You can usually touch the finished product immediately.

Variable Data Printing

One of the significant benefits of digital printing is its variable data capability. Often referred to as VDP (Variable Data Printing), this useful option allows each printed piece to change data from one sheet to the next, even for pages in a collate print sequence. How? The computer communicates directly with the machine.

For example, say you have a set of personalized invitations. Each one needs a specific and different address. With VDP, you can print each one with a different name or address, one by one. (Whereas with offset printing, each change requires changing an entire printing plate!)

This option can be a great tool with several applications.

- Direct Mail Marketing

- Advertising, Flyers

- Mailers, Newsletters

- Postcard Campaigns

- Magazines

Breaking Down Digital Printing vs. Offset Printing

Lower Setup Costs

Winner: Digital Printing

Setup isn't a huge factor when you have a massive print project. But, it can be a waste of money for smaller batches or quick turnaround projects.

That's where digital printing saves the day. It's by far the quickest option for short runs, especially if multiple originals need to print. There is virtually no setup time.

Exception: That said, there are specific jobs when setup time doesn't matter. For example: Sometimes a print project requires a certain degree of style or class. Let’s imagine an art gala invite. The creatives hosting the events would like a particular top-of-the-line paper. Cost and time aren’t a factor. In this situation, you might want to stick with offset printing. It provides more print material options and room for those extra unique embellishments.

Volume and Cost-Effectiveness

High Volume

Winner: Offset Printing

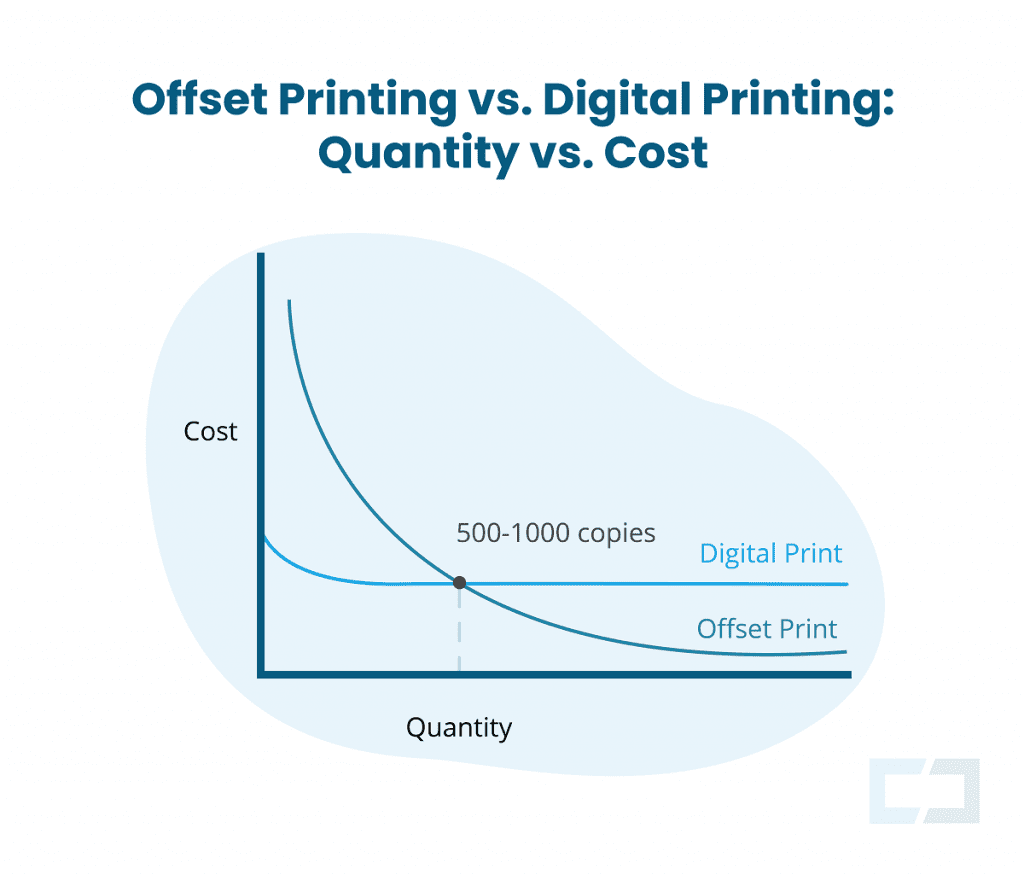

Offset printing costs plummet once the quantities are above 500-1,000. The exact number varies depending on the competing digital printer.

There are initial setup costs and time constraints, but once you reach a certain threshold, the sky's the limit. You can't beat the rapidity of the offset printer, the quality of the final product, and the efficiency of the machine.

Low Volume

Winner: Digital Printing

As we've said, digital printing takes no time at all to set up. The quality level for such a quick turnaround is closer to offset printing than ever before. So for small batches, digital printing wins easily.

Think of projects that have a lot of single or low-quantity copies as the best example. Or, print runs that require VDP, that variable data component we mentioned before.

Digital printing gives the most flexibility while remaining budget-friendly, even if you only have a few copies to make.

Speed

Low Volume

Winner: Digital Printing

For a rush project, think last-minute running through the doors of the print shop: digital wins. The name itself implies that it has the technology and agility of modernity, and so it does.

High Volume

Winner: Offset Printing

While digital is speedy because there is no setup, the machine itself tends to work slower. So, if there is a massive project to print out, then it will take longer on a digital printer despite having no extra setup time.

Luckily, once those aluminum plates are good to go, that offset printer can spit copies out faster than you can count.

Quality

Winner: Offset Printing

Digital printing produces thousands and thousands of tiny dots to recreate the final design.

Offset printing, however, is a replica of the detailed design. The inked design is pressed directly onto a surface to create a more saturated and softer image.

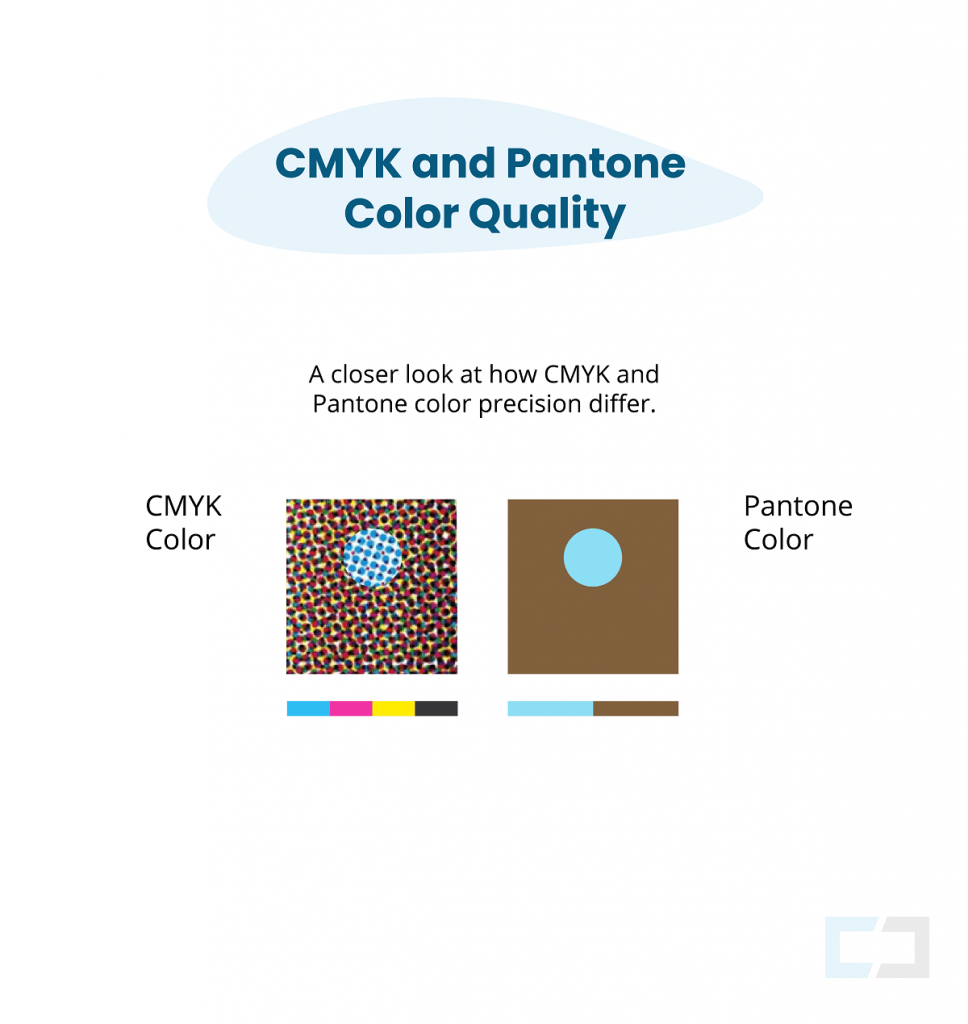

While it can certainly be a matter of taste, overall, the level of quality of offset printing is hard to match. It can produce solid ink coverage prints (think of those glossy magazine covers). Plus, it can even print exact Pantone color options on a wider range of surfaces.

Even when printing type, it's easy to spot the differences between digital and offset. Softer colors can often reveal the tiny dot system even on something simple such as text and font. You can take a closer look here.

While we will cover color as a standalone factor more below (it plays a big part), the real difference in quality is this: tiny dots of color vs. a fully inked design.

Color Options

CMYK

Winner: Tie

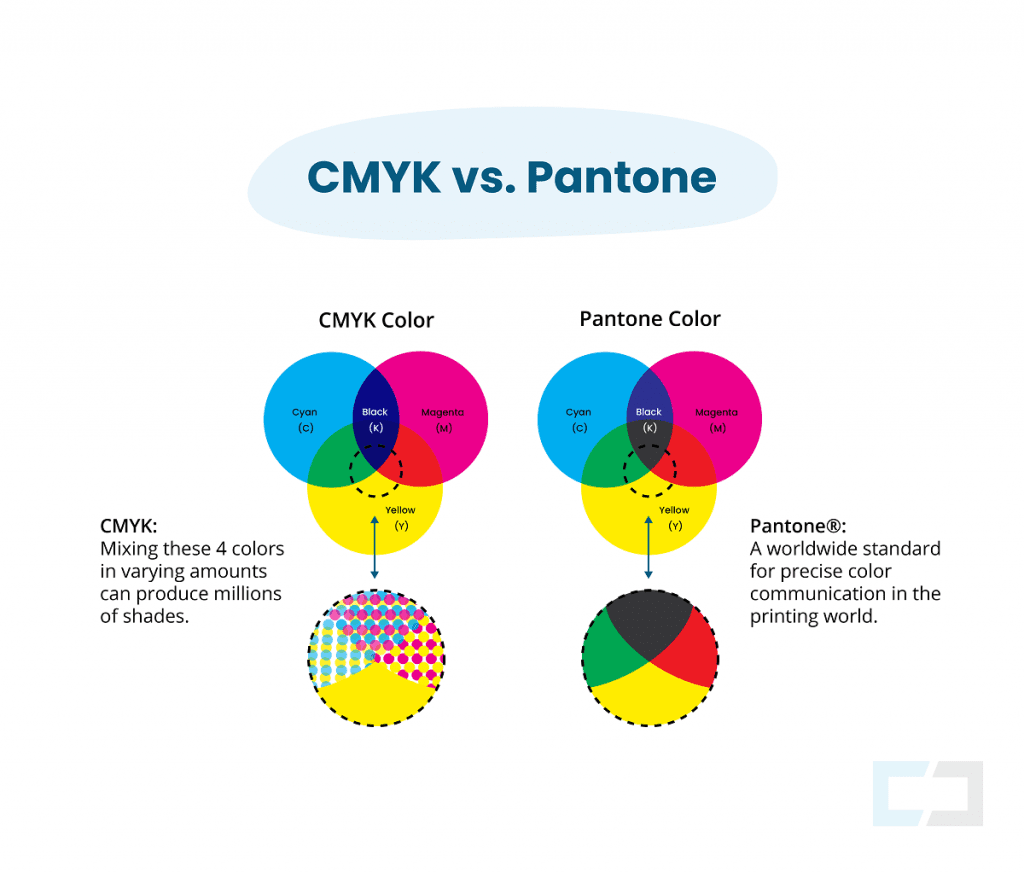

CMYK stands for cyan, magenta, yellow, and black. This is the standard color model for commercial printing.

Digital printing mixes the four colors in varying amounts to produce millions of shades. It's, of course, the same with Offset printing, but the colors layer one by one in this order: cyan, magenta, yellow, and then black.

Pantone Precision

Winner: Offset Printing

Color management is of utmost concern to brands, in particular. That’s where the Pantone colors win the show. Their pure and potent colors go into the press and transfer onto the material of your choice. There’s no color mixing or diluting of intensity like with CMYK.

The official Pantone® Matching System (PMS) allows for brand consistency across the world. These colors are uniform, no matter where you are and offer perfect color reproduction.

This option is not yet available with digital printing equipment.

Black & White

Winner: Offset Printing

With just one color needed to achieve this color “combo,” offset printing would undeniably be the best option. Think about the classic forms of print, such as newspaper printing and book printing.

Exception: Lower quantity jobs, anything less than 500, go for digital— unless you prefer the quality of offset.

Special Finishing Processes

Winner: Offset Printing

Print finishes are more than the icing on the cake. They are the glistening sprinkles that make your final print job shine.

Offset printing services offer options such as varnish, foil stamping, embossing, and more. All the things that can transform a regular ol’ sheet of paper into an elegant folio or cutting-edge print.

Digital machines often have time-saving abilities such as die-cutting, folding, and laser cutting. But, unfortunately, their inks and toners don't respond well to the heat and pressure of these special finishes.

Print Surface Options

Winner: Offset Printing

One significant advantage of many digital printing presses is their ability to fold and stitch. However, that means the paper used has limits. It must be able to fit precise specs that give it room to get that extra task done. Another limitation? The way the ink sits on the paper surface does not jive well with textured papers like linen and felt.

Offset printing, on the other hand, creates stunning prints on a variety of textured or unique materials. Still achieving high-quality, professional jobs. The print surface options cover a wide range: wood, cloth, metal, leather, rough paper, and even plastic.

Note: Digital print technology is more advanced than ever. These machines can now often print on up to 18 point stock. Keep in mind, some jobs might be better for digital printing, and it can often boil down to a matter of taste. It’s a popular pick for printing digital photography, plus digital printing in this arena offers a substantial range of print material options.

Size Options

Winner: Offset Printing

Digital print runs are generally limited in size. That doesn't at all mean that large format printing isn't an option for digital. It's just that, when sizing digital vs. offset printing up side by side, offset wins.

Most models of large-format offset printers can handle larger paper types. We're talking up to 41˝, 44˝, 47˝, 54˝, 56˝ and even 64˝. The sheer grandiose of the offset press allows a much larger size to run through.

Though not as large as offset options, digital printers still hold their own—the paper measures around 20″ and up to 35″ in some cases.

Exception: As usual, if the print volume is lower, digital print is the best option.

Do you need print proof?

Winner: Digital Printing

When it comes to offset printing, the hurdle to cross is always the prepress task. That plate prepping time factor plus the price of the ink adds up quickly. For a single proofing run, that can be quite costly.

So, if you need to see a print proof before you take the plunge to invest in the print job, digital printing is the better option. It can whip out a single business card for you to see a quick sample, and you can make small adjustments before committing to larger quantities.

Variable Data Printing (VDP)

Winner: Digital Printing

There's no contest here. Digital printing provides VDP capability that offset printing does not. So each printed page can reflect a unique name, address, or any other desired variables.

With offset printing, this would be a manual job.

Take your pick

When it comes to digital printing and offset printing, both offer excellent solutions to complete a print job.

Depending on your print job, both print options provide results that can either align or break with your budget or style goals. Choosing the best process for your job is a simple matter of reviewing the pros and cons, and determining which factors are a priority for the job at hand.

Whether digital or offset takes the cake, the two options are top of the line, verified, and efficient print processes used all the time.

Do you have a print job requiring digital or offset print services? Contact us to get plates for offset printing!

Contact form

- การเลือกตัวเลือกจะส่งผลให้มีการรีเฟรชทั้งหน้า