In the future, the printing industry will have higher and higher requirements on the quality of printed matter, and the traditional backward printing process can no longer keep up with the pace of the times, forcing many printing factories to abandon the traditional plate-making technology and adopt CTP plate-making.

Compared with the traditional plate-making technology, computer-to-plate technology (CTP) has the advantages of reducing the process links, saving materials, space and labor, shortening the production cycle, etc., and because of the reduction of human factors, the plate-making quality can be well controlled, especially for publishing Timeliness is extremely important. For newspapers, the introduction of CTP plate-making technology can also delay the deadline and improve the quality of image-text reproduction (because in image-text replication, one less process means less distortion), shortening plate-making time and printing start-up time.

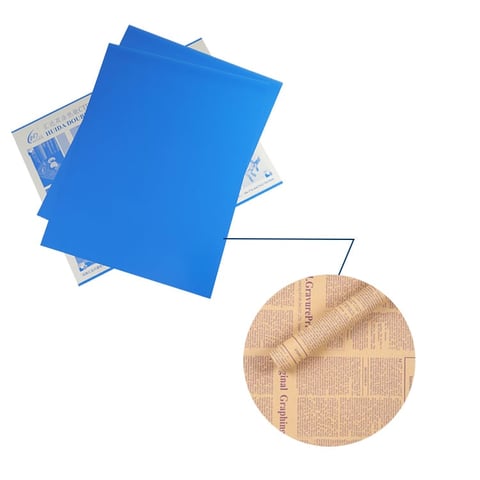

A complete set of CTP plate processing system includes developing, washing, fixing, drying and other processes, each of which affects the quality of plate making, so a CTP plate processor with superior performance must be equipped with these four procedures. control. In addition, the temperature and humidity control of the plate processor also affects the quality of plate making, so a plate processor must maintain a stable plate making environment,

Guarantee the identity of variables in the plate making process