Thermal CTP mainly uses thermal imaging technology, relying on the printing plate material to absorb heat and change the state of the material, thereby achieving changes in material properties.

Plate composition

The thermal decomposition plate is composed of a heat-sensitive coating and a hydrophilic plate base. The heat-sensitive coating is generally composed of a water-insoluble (alkali) film-forming resin and an infrared dye; the hydrophilic base can be an aluminum base.

Imaging principle

The function of the infrared dye is to effectively absorb the light energy of the infrared laser and convert the absorbed light energy into heat energy, so that the temperature of the heat-sensitive coating can reach a level that weakens the chemical bonds of the film-forming resin on the surface of the plate and decomposes, thereby making the heat-sensitive coating The coating is water (alkali) soluble. The heat-sensitive coating in the light-exposed area undergoes a decomposition reaction under the action of heat and is alkali-soluble. It is dissolved during the development process, exposing the hydrophilic plate base and becoming a hydrophilic blank part; the heat-sensitive coating in the non-light-exposed area does not. A decomposition reaction occurs and it is not alkali-soluble. It remains on the page and becomes a lipophilic graphic part after development.

Characteristics:

① The thermal CTP plate has very low sensitivity to natural light and uses infrared laser exposure, so it can be operated under bright room conditions.

② To generate an image, the thermal plate must reach the initial thermal energy threshold, and the thermal energy higher than the initial threshold will not change the shape of the dots. It is the only technology that can control the predictable results. The quality is easy to control, the publishing quality is stable, and the print after exposure The plate can be extended to 6 months before development without any impact on the quality of the plate.

③ The thermal plate has good dot reproducibility, high resolution, and sharp and clear dot edges. It is easy to achieve ink and ink balance during printing, has good printability, and the printing endurance of the baked plate can reach 1 million prints. above.

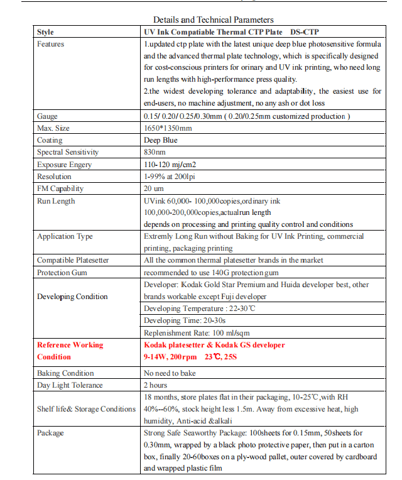

Huida Print-All Technology company is an advanced and professional manufacturer of producing printing plates, mainly sales CTP, CTCP, and PS plates as well as offering ODM/OEMs, especially for the offset. For more information, please click the official website link here: https://www.huidaoffsetplate.com/.